Efficient pneumatic locking system for chase. Computerised control display with 3D touch screen,allowing instant machine status reading and error indentification

Adopt the pallet collection paper,flexible and comfortable,to increase the work efficiency.Adopt photoelectric detection to insure smooth and steady delivery

Leading edge-cutting indentation machine

参数 | 1300 | 1520 |

最大输出纸尺寸 | 1300*940mm | 1520*1100mm |

最小输出纸尺寸 | 500*450mm | 550*450mm |

最大模切尺寸 | 1280*920mm | 1500*1080mm |

最大模切压力 | 300N/cm² | 300N/cm² |

可加工纸张 | 200-2000g/m² 1-8mm | 250-2000g/m² 8mm |

机器最高速度 | 4500SH | 4500SH |

纸张纸堆最大高度 | 1300mm | 1600mm |

总功率 | 15KW | 18KW |

整机重量 | 15T | 19T |

The final interpretation of the above data belongs to ZY Packaging, and the parameters are subject to change and structural improvement without prior notice.

Advantages :

Upgrade and optimize the main transmission system.

High work efficiency and good die cutting accuracy.

The machine is reliable, durable, and fully functional.

High safety and convenient maintenance and testing.

Short version change time and convenient operation for the calibration machine.

Optimization of blade and waste cleaning standards, which can be used with other fully automatic equipment.

What else we can offer:

The design of the fully automatic flat pressing die-cutting machine emphasizes the need for personnel who have never operated the die-cutting machine to be able to operate it immediately after rapid training. Therefore, all operating buttons, handles, and handwheels are designed and assembled according to the concept of simplicity, practicality, safety, and reliability. After the contract is officially established, we provide customers with two aspects of training: machine operation and use, troubleshooting, common maintenance and repair explanations and training. Generally, the first part of the standard course provided by our company is five working days, and the second part is three working days (at your company's production site). Provide training and guidance on die-cutting processes for customers based on their product characteristics.

1. Adjustment and operation of the die-cutting machine

2. Production and processing technology of die-cutting knife plate

3. Indentation of cardboard and the use of indentation strips

4. Selection and correct use of sponge adhesive strips

5. Use of various auxiliary molds

after-sale service

1. After sales plan

The performance and quality of the machine equipment itself are excellent. 365 days of dedicated duty personnel for consultation.

2. We promise to provide free technical consulting services and technical guidance on die-cutting processes to the buyer.

3. Fast and effective after-sales service, we provide 12 months of free equipment maintenance service and regular follow-up visits.

4.When the machine malfunctions and the buyer cannot eliminate it, the manufacturer promises to have the service technician arrive at your company for service within 36 hours. Common operational faults can be found in the troubleshooting manual in the manual.

5. We promise to provide year-round equipment maintenance and services. Provide operation instructions, technical documentation, common operation troubleshooting manuals, electrical schematic diagrams and other technical documents

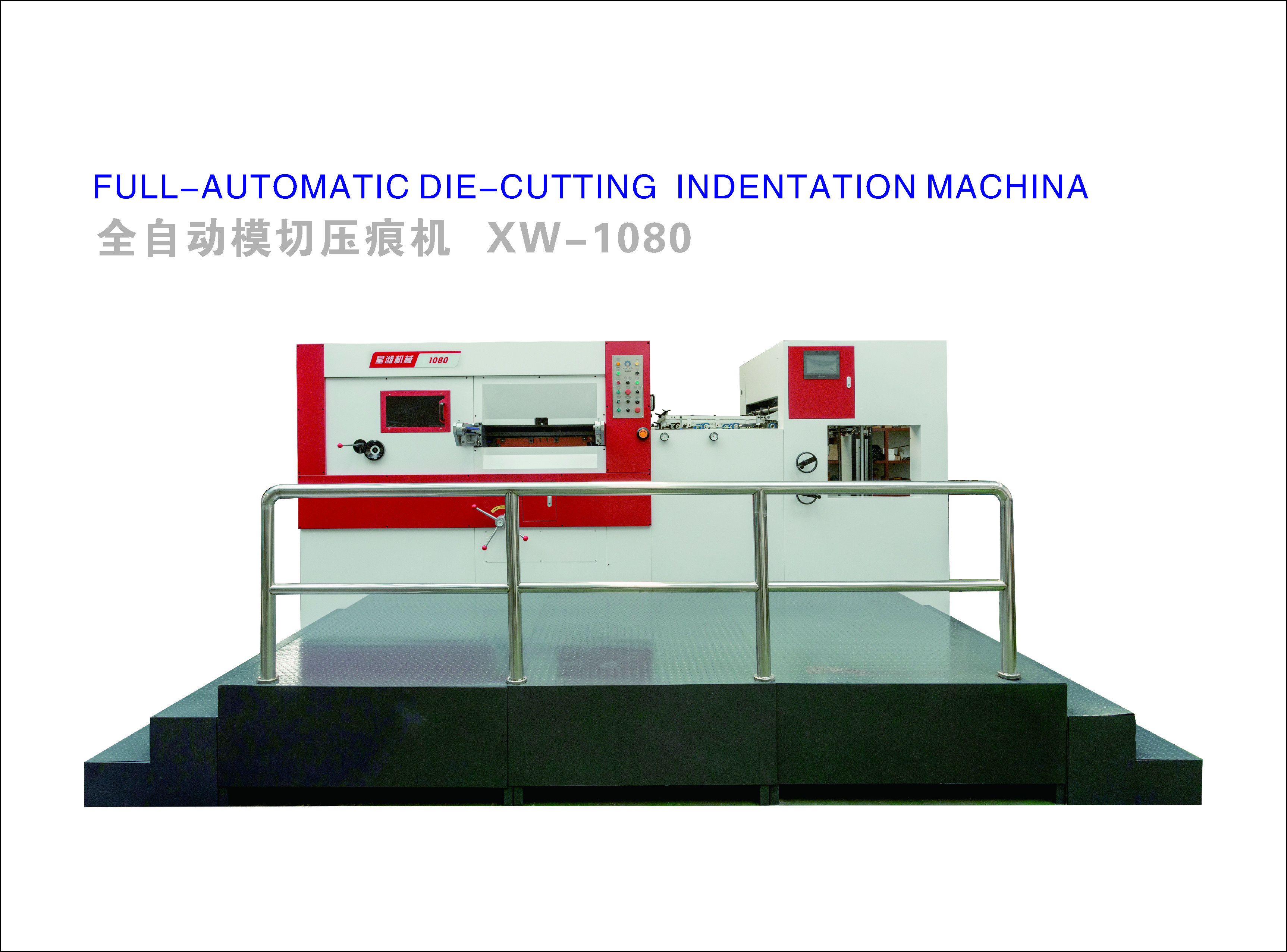

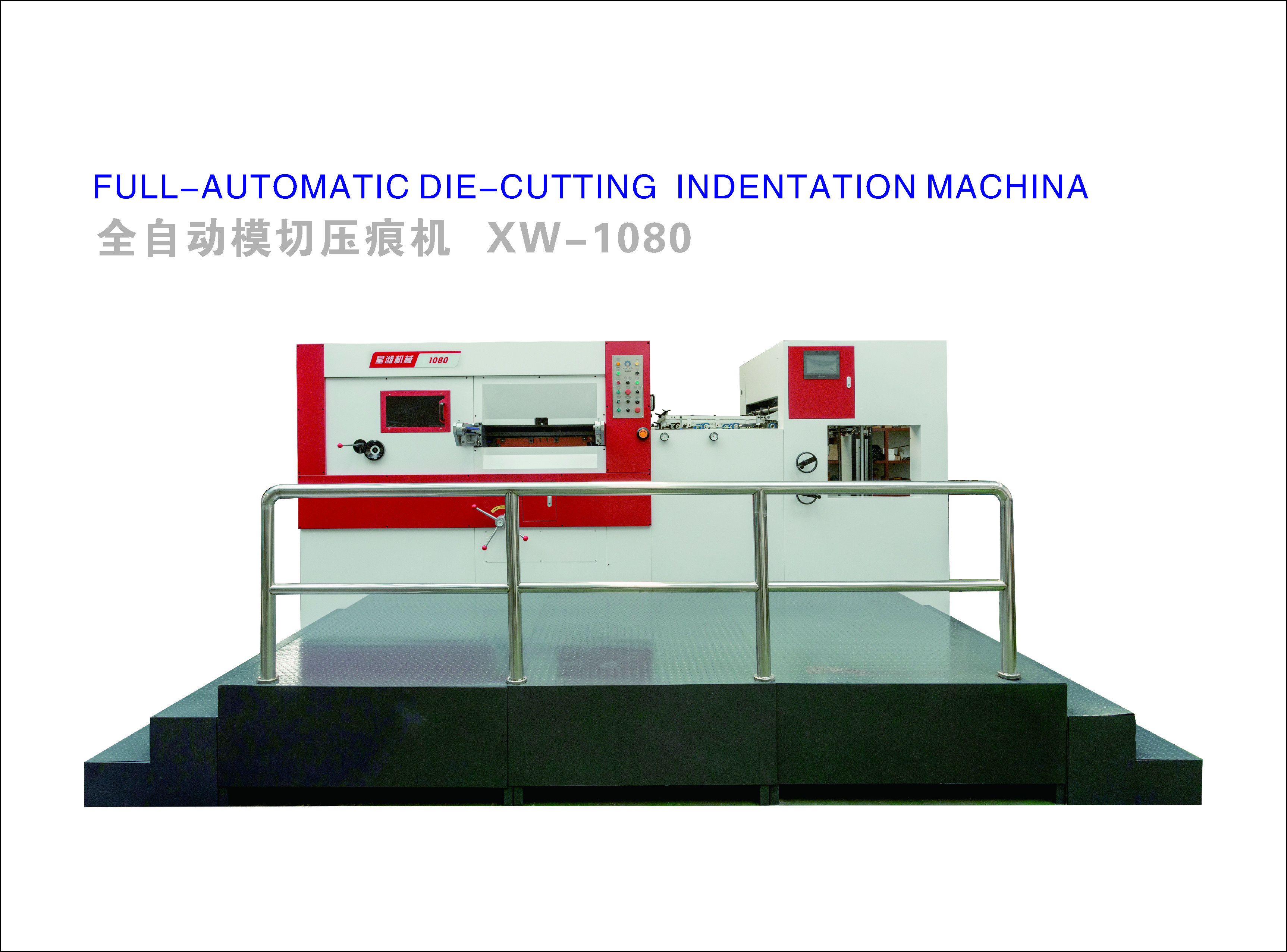

full-automatic die-cutting indentation machine

full-automatic die-cutting indentation machine

Leading edge cleaning-die-cutting and indentation machine

Leading edge cleaning-die-cutting and indentation machine

Semi-automatic die-cutting & creasing machine

Semi-automatic die-cutting & creasing machine

full-automatic die-cutting indentation machine

full-automatic die-cutting indentation machine

Leading edge cleaning-die-cutting and indentation machine

Leading edge cleaning-die-cutting and indentation machine

Semi-automatic die-cutting & creasing machine

Semi-automatic die-cutting & creasing machine